2 gas requirements, 3 connecting the gas supply, 1 checking the gas line for leaks – Thermador Professional Series Gas Rangetop Installation Instructions Manuel d'utilisation

Page 14: 2 propane gas connection

en-us

Gas requirements and connections

14

¡

If desired, for altitudes above 2,000 ft (610 m) elevation

above sea level, adjustments can be made to the

rangetop burners with an adjustment kit. If flame perfor-

mance is satisfactory, adjustment will not be required.

¡

See Customer Service information about service, parts,

and accessories.

7.2 Gas requirements

Natural gas requirements:

¡

Inlet connection: ½" NPT internal (min. ¾" diameter flex

line)

¡

Supply pressure: 7" min. to 14" max. water column

(17.4 to 34.9 mbar)

¡

Manifold pressure: 5" water column (12.5 mbar)

Propane gas requirements:

¡

Inlet connection: ½" NPT internal (minimum ¾" diame-

ter flex line)

¡

Supply pressure: 11" min. to 14" max. water column

(27.4 mbar to 34.9 mbar)

¡

Manifold pressure: 10" water column (24.9 mbar)

7.3 Connecting the gas supply

1.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

2.

Use a ¾" (19 mm) flex line to connect between the gas

supply and the appliance gas inlet. The gas supply line

connection is located at the lower right portion. The ap-

pliance gas inlet connection is ½" (12.7 mm) NPT.

‒

Use caution to avoid crimping the ¾" (19 mm) flex

line when making bends. Suggested length of flex

line is 48" (1219 mm); however, please check local

codes for your area's requirements before installa-

tion.

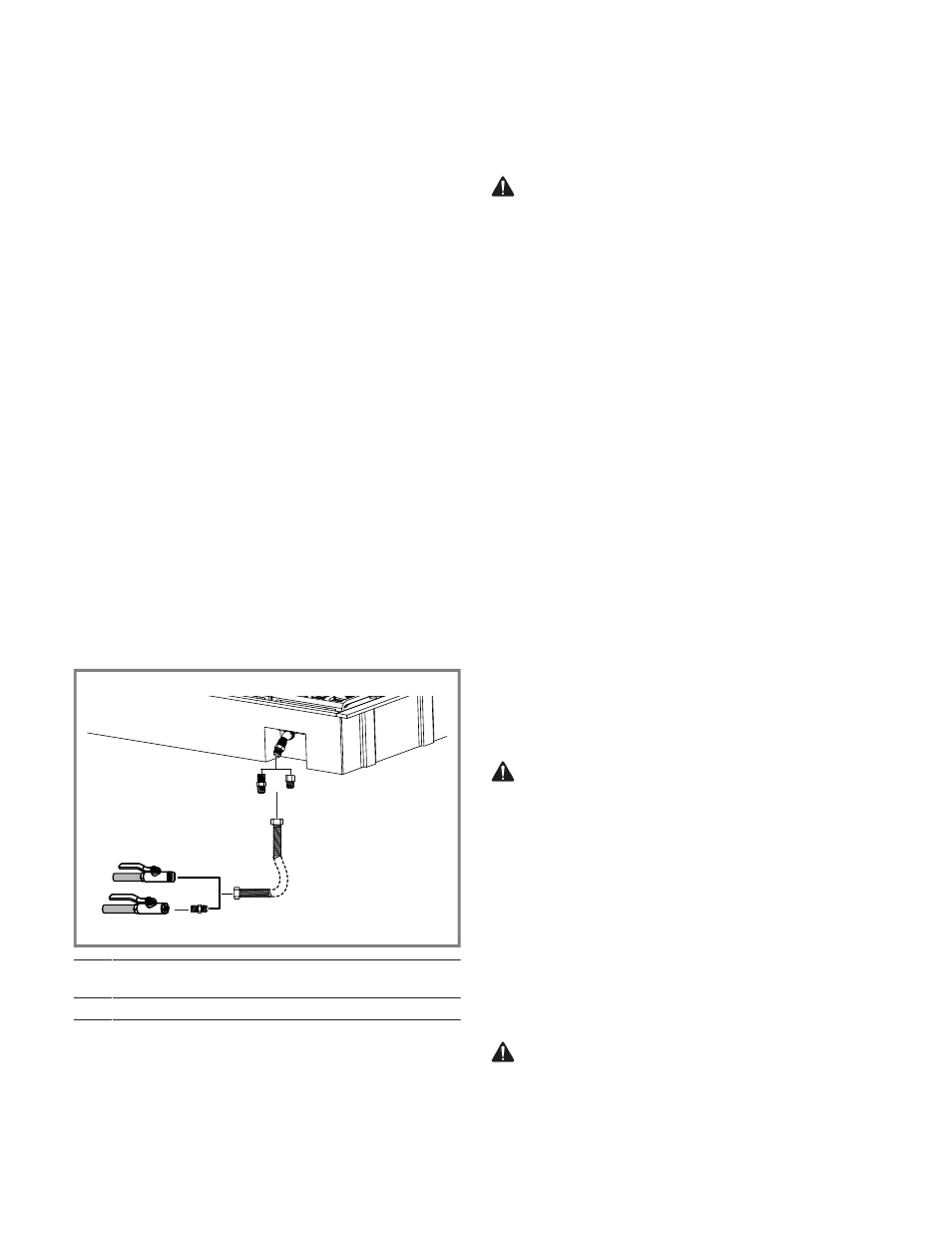

{

A

B

A

¾" (19 mm) external threads

½" (12.7 mm) internal threads

B

¾" (19 mm) flex line

3.

Use pipe sealing compound or Teflon® tape on the pipe

threads. DO NOT apply sealing compound or tape to

flare fittings. Take care not to apply excessive pressure

when tightening the fittings.

4.

Leak testing of the appliance shall be in accordance

with the following instructions:

‒

Turn on gas and check supply line connections for

leaks using a soap and water solution.

‒

Bubbles forming indicate a gas leak. Repair all leaks

immediately.

Checking the gas line for leaks

Leak testing must be conducted by the installer according

to the following instructions.

WARNING

DO NOT use a flame of any kind to check for gas leaks.

1.

Turn on gas.

2.

Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the shut-off

valve and the appliance. Also check gas fittings and

joints in the appliance if the connections may have been

disturbed during installation.

a

Bubbles appearing around fittings and connections indi-

cate a leak.

3.

If a leak appears, turn off the supply line gas shut-off

valve and tighten the connections.

4.

Retest for leaks by turning on the supply line gas shut-

off valve.

a

When the leak check is complete and no bubbles ap-

pear, the test is complete.

5.

Wipe off all soap solution or detection fluid residue.

a

Do not continue the installation until all leaks are elimi-

nated.

Propane gas connection

Your appliance is shipped by the factory to operate on nat-

ural gas. It must be converted for use with propane gas.

Verify the type of gas being used at the installation site

matches the type of gas used by the appliance.

If the location site requires conversion from natural gas to

propane (LP), contact the dealer where the appliance was

purchased or contact Thermador to purchase a conversion

kit. Obey all instructions in this kit for correct conversion of

the gas regulator and settings for the gas valves. Field

conversion must be done by qualified service personnel

only.

WARNING

When using a gas conversion kit:

▶

The gas conversion kit shall be installed by a qualified

service personnel in accordance with the manufac-

turer’s instructions and all applicable codes and require-

ments of the authority having jurisdiction.

▶

If the information in the instructions is not followed ex-

actly, a fire, explosion or production of carbon monoxide

may result causing property damage, personal injury or

loss of life.

▶

The qualified service personnel is responsible for the

proper installation of the gas conversion kit.

▶

The installation is not proper and complete until the op-

eration of the converted appliance is checked as speci-

fied in the manufacturer’s instructions supplied with the

gas conversion kit.

CAUTION

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve dur-

ing any pressure testing of the gas supply piping system at

test pressures equal to or less than ½ psi (3.5 kPa).